|

|

|

|

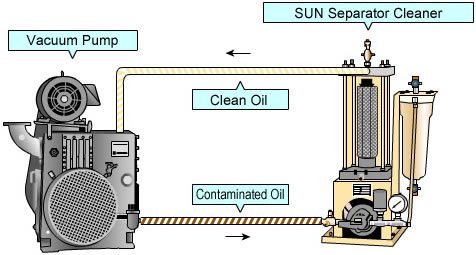

@SUN Separator Cleaner System Construction |

|

|

Benefits |

|

Reduces the need for oil removal from the rotary oil vacuum pump |

|

Keeps the vacuums pressure at an optimal level |

|

Increases productivity and reduces the need for maintenance

work |

|

|

|

|

Structure |

|

|

|

| @Separator Element |

|

|

The Separator Element removes any water from oil by utilizing the water

adsorptive function of the engineered ion exchange fiber.

A water film is formed inside the Element that traps any water that is contained in the oils as it passes through. The water then becomes assimilated and separated through the specific gravity differences in water and oil. |

|

|

|

| (Function) |

Removes water continuously from Vacuum Pump oil. |

|

| (Theory) |

The Separator Element separates water and oil by utilizing gwater-filmh. |

|

| (Innovative) |

Clogging of the mesh in Element fiber takes time, thus it can maintain

oil and water separation for a long time.

|

|

| (Features) |

@The Separator Element has been developed by our own technology

and it is the element of oil-water separation with the rough mesh of fiber.

Water absorptive function of inner Element absorbs water and forms

gWater-Filmh uniformly. The gwater-filmh is our know-how.

When very fine waterdrop passes through the Element, it becomes

assimilated and separated through gravity differences in water and oil.

This is oil-water separating fiber element strong against contaminated oil.

|

|

|

| @Separator Element Features |

|

|

Separates fine water particles |

|

The durable water film protects against contaminants |

|

High functionality and a long lifespan |

|

|

|

@Applications |

|

| Compatible Oils: |

Vacuum Pump Oil, Hydraulic Oil, Lubricant Oil, Fluorine Oil, Synthetic Oil, Insulation Oil, Hydro Carbon Liquid, etc. |

|

| Applicable Devices F |

Vacuum Drying, Vacuum Deposition, Vacuum Brazing, Distillation, Vacuum Packing, Vacuum Freeze Drying, Heat treatment, Vacuum Impregnation, Other Vacuum Devices and Machines. |

|

|

|